Small Flock Turkey Production, by Penn State Poultry Extension

Amy Barkley, Livestock Specialist

Southwest New York Dairy, Livestock and Field Crops Program

Small-Flock Turkey Production

Prepared by R. Michael Hulet, associate professor of poultry science (retired), Phillip J. Clauer, senior extension associate, George L. Greaser, senior extension associate (retired), Jayson K. Harper, professor of agricultural economics, and Lynn F. Kime, extension associate.

This publication was developed by the Small-scale and Part-time Farming Project at Penn State with support from the U.S. Department of Agriculture-Extension Service, February 11, 2005.

Updates and edits made to outline considerations specific to New York State were made by Amy Barkley.

Introduction:

Raising turkeys can be a satisfying educational activity as well as a source of economical, high-quality meat for your family and friends. They can easily be started by hatching eggs or by raising young poults. They can be grown and home processed without the use of expensive processing equipment, or they may be sold to live markets (auctions), customers, or neighbors.

Turkeys are either of two bird species in the family Meleagrididae (order Galliformes). The best known is the common turkey (Meleagris gallopavo), a game bird native to North America but widely domesticated for the table. The other species is Agriocharis (or Meleagris) ocellata, the ocellated turkey.

The common turkey was probably first domesticated by the Indians of pre-Columbian Mexico. The birds were first taken to Spain about 1519, and from Spain they spread throughout Europe, reaching England in 1541. When the birds became popular in England, they were called by the name turkey-cock, a name formerly used for the guinea fowl of Islamic lands. English colonists then introduced European-bred strains of the turkey to eastern North America in the 17th century. Turkeys were bred mainly for their beautifully colored plumage until about 1935, after which the breeding emphasis changed to their meat qualities.

Adult males have a naked, heavily carunculated (bumpy) head that normally is bright red but that turns to white overlaid with bright blue when the birds are excited. Other distinguishing features of the common turkey are a long red fleshy ornament (called a snood) that grows from the forehead over the bill; a fleshy wattle growing from the throat; a tuft of coarse, black, hairy feathers (known as a beard) projecting from the breast; and more or less prominent leg spurs. The male wild turkey (variously called a gobbler, tom, or jake--immature male), may be 50 inches long and weigh up to 22 pounds, although the average weight is less. Female turkeys (hens) generally weigh only half as much and have less warty heads. Domesticated strains of the common turkey, developed for their fine-tasting flesh, may be much heavier.

In many European countries roast turkey has long been a customary Christmas dish. In the United States the bird is especially associated with Thanksgiving. Turkey production has thus tended to be seasonal, although in the United States and some other countries, ready-to-cook, lean, boned turkey is available in rolls any time of the year. In New York State, turkey pieces (drums, thighs, bone out breasts, etc.) and specialty turkey products (smoked, sausage, stock, etc.) can be value added alternatives that are sold year-round.

The "breeds" of turkeys often referred to are actually varieties that originated from the North American wild turkey. The most commonly raised commercial variety is the Large White. The Broad-Breasted Bronze, similar in size and conformation, is less popular because of a preference for white feathering. However, a wide variety of hobby breeds--Bourbon Red, Black, Slate, Holland White, Narragansett, Broad-Breasted Bronze, Royal Palm, and other stock can also be ordered from hatcheries. While nice to look at, most of these hobby strains do not grow as fast and as efficiently as the commercial turkey strains. Three common commercial strains have been developed and sold by companies in the United States: Nicholas Turkey Breeding Farms, Aviagen Turkeys, and Hybrid Turkeys. Many large commercial and mail-order hatcheries have access to these genetic lines, selling production-type poults with excellent feed conversions and finish weights.

Marketing and Processing:

Before beginning your operation, you should examine your objectives for producing turkeys; this will help ensure your success. A small number of turkeys can be raised in a relatively small area, but you will need to obey local zoning laws and ordinances in order to rear, process, and sell poultry without neighbor complaints.

If you plan on direct sales of turkeys from your small-flock production, you must make plans for processing (if selling whole carcasses or parts), plans for making value-added products, transporting of live or processed turkeys, and timing of the production to match the needs of your clientele. Local markets (auctions, live markets, etc.) and grocers can also provide opportunities for selling your excess production. If you plan on selling processed turkeys, you may find it more convenient to have them custom processed. Alternatively, in NYS, up to 250 turkeys per year can be processed under the NYS 1,000 bird exemption.

State and federal laws regulate the sale of processed birds. Limited processing of fresh turkeys (fewer than 250 birds per year) for direct sale to consumers is legal as long as sales do not cross state lines. Processing turkey into value-added products will require a 20-C license and processing in a 20-C kitchen. Products produced this way can only be sold to the end consumer by the producer, and these too many not cross state lines.

Production and Management:

While caring for turkeys requires little daily time, you must provide regular and timely care to be successful in getting a flock to market. Some basic management practices are necessary for success. First, it is essential to obtain stock from a known disease-free source. Stock should originate from hatcheries that are members of the National Poultry Improvement Plan (NPIP). Members regularly test and eliminate stocks with egg-borne diseases, including pullorum, and can also include typhoid, paratyphoid, and pleuropneumonia-like organisms (PPLO). To further reduce the threat of disease, raise turkeys away from other poultry. Mycoplasma galacepticum (MG) and histamoniasis (blackhead) can be serious problems for turkeys raised among chickens or on grounds where chickens have been within the previous three years.

If you purchase fertile eggs for incubation, they must be kept in a clean environment at an ambient temperature between 55° and 65°F prior to setting. Eggs can be held for only about seven to ten days before setting without a serious decrease in hatchability. Set only clean eggs at a temperature of 99.5° to 100°F for 28 days. Turn the eggs at least twice daily for 25 days. Eggs should not be turned the last three days prior to hatch. After the hatch is complete, remove the poults and hatch residue.

Poults start more easily if brooded within 48 hours after hatching, and it is very important to prepare your brood chamber properly. Poults need a warm, draft-free environment that is well ventilated and that has free choice of feed and water. Since poults are unable to regulate their body temperature for the first 10 days, a properly managed heat source is necessary. The most efficient heat source will depend on your particular housing situation. Set the room temperature at approximately 88°F with a temperature of around 95°F under the heat source. Round all corners of the brooding area with cardboard or wire to prevent birds from smothering. Poults can be scared easily by loud noises, sudden movements, or bright lights, causing them to crowd on top of one another, which can be fatal.

The brooder guards are usually used for the first week or two to help keep the poults near heat, feed, and water sources. It may be necessary to dip poults' beaks into the water and feed to start them drinking and eating. Observe the birds carefully to see if they are too hot (positioned far away from the heat source) or too cold (huddled together). Comfortable poults will spread uniformly under and around the edge of the brooder. Gradually decrease the room temperature each day (5°F per week) until it reaches 70°F. Keep the lights dim during the poults' first week; afterward, 12 to 14 hours of light is sufficient. Excessive light intensity or light spots in the turkey house can cause piling or cannibalism in young poults.

Managing the litter to keep it dry pays big dividends in the health of a growing turkey. Cover the brooding area with at least two inches of litter. A good litter is clean, dry, absorbent, and relatively free from dust. Commonly used litter materials include wood shavings, chopped straw, peat moss, or other commercial litters. During the brooding phase, it is recommended that peat moss be used as the top layer of litter. This practice prevents the poults from ingesting the litter, which blocks their digestive processes. Since litter absorbs moisture and insulates the birds from the cold floor, it is important to remove any areas that become wet and to add more litter as needed. Do not cover litter with slick-surfaced materials (such as newspaper), as these can cause serious leg injuries to poults.

Poults are usually brooded in an area with a density of one square foot per poult for the first five to six weeks; then they are moved to a finishing barn or outside to a finishing area. When poults are from eight weeks to market age, provide three to five square feet of confined housing space per bird, depending on the weight to which they will be grown. In confined housing, ventilation becomes increasingly important as the turkeys get larger and as hot weather approaches. As they get larger turkeys need more air circulation--0.5 cubic feet per minute (cfm) per pound of body weight at a minimum and to help dissipate the heat as the temperature gets warmer. Air speeds of 400 cfm on their heads can help cool the birds in high heat situations in enclosed barns.

Feeding and Watering:

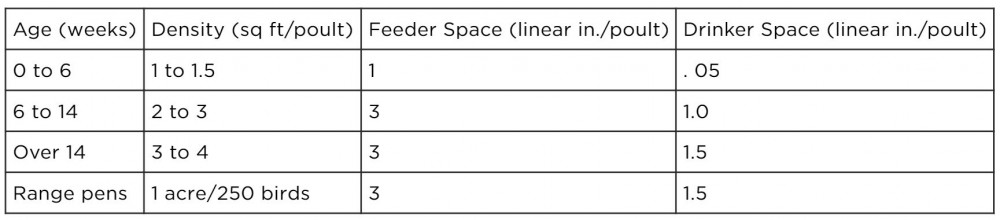

Feed and water should be available to the growing turkeys at all times. Some flocks seem to have trouble finding the feed early, resulting in death loss from "starve outs." Some producers put marbles or aluminum foil balls in drinkers and feeders for the first two weeks to attract the turkey poults and start them on feed and water. Adequate feeder and drinker space ensures that all birds in the flock have an opportunity to eat and drink. See below for feeder and drinker spacing recommendations.

Recommended minimum density, feeder, and drinker space for turkeys (click table to enlarge)

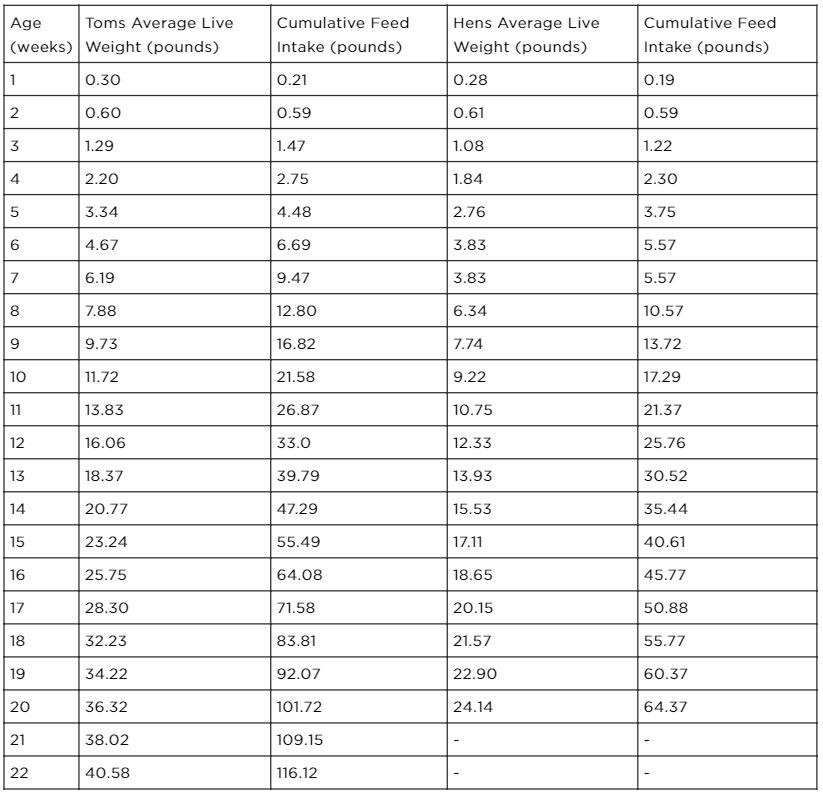

All commercial turkey varieties produce meat efficiently. Hens commonly reach a live weight of 15 pounds at 14 weeks of age, and toms weigh about 28 to 30 pounds at 17 to 18 weeks. The table below shows the expected average weights and cumulative feed consumptions of tom and hen turkeys at various ages.

Growth weight and cumulative feed consumption of Large White tom and hen turkeys (click table to enlarge)

From: Peter R. Ferket, Watts Electronic Publications, 2002

Turkeys are fast-growing, efficient converters of feedstuffs to high-quality meat. Feeding properly balanced rations results in the best performance. Poults should be given turkey crumbles containing 28 percent protein for four weeks. This gets the birds off to a good start while their feed intake is relatively low. A turkey growing ration (either crumbles or pellets) containing 26 percent protein is recommended for poults four to six weeks of age.

Feeds containing less protein can be fed after poults are six weeks old. Complete growing rations with lower protein levels may be purchased, or you can include concentrates with cracked grains (about 10 percent protein), such as corn and oats, along with the growing ration to increase energy and reduce protein intake. For example, one part grain to three parts of a 22 per¬cent protein growing ration will provide a 19 percent protein mixture, which is satisfactory for turkeys from 10 to 12 weeks old. For birds from 12 weeks of age to market, mix equal parts of grain and the growing ration to provide 16 percent protein. Grit should be available if whole or cracked grains are used.

Check the protein level of the finishing ration to determine whether to continue mixing grains with the ration. The protein level should not drop below 16 percent. Some growing feeds contain drugs to control diseases; the feeding of these drugs must be discontinued for a specified length of time before the turkeys are slaughtered. This information should be given on the feed tag. Feed manufacturers also provide finishing rations without drugs. During the finishing phase, feeding free-choice whole corn will improve the finish, tenderness, and flavor of the processed bird.

Health Programs:

Management is the key to maintaining the health of your flock. Good sanitation and elimination of other birds and animals that may carry disease organisms are important for maintaining a healthy flock. Keeping the pen and range areas dry also helps. Vaccines, available for several turkey diseases, are not necessary for a small flock unless previous disease problems existed on your premises or on nearby farms. Other disease problems can be controlled through the use of medicated feeds, if necessary. However, clean stock, clean premises, and good management are the best lines of defense.

If your flock does become sick, an accurate diagnosis and recommended treatment should be obtained as quickly as possible. State diagnostic laboratories usually offer low-cost or free diagnostic services. Take birds with representative symptoms or fresh, dead birds to the laboratory for evaluation. Along with the birds, take a complete flock history including age, feeding program, vaccinations, or drugs used, and a description of the course of the current problem. Some death loss is normal and should be expected, especially during the first two weeks. However, it is important to get an early diagnosis of the problem in order to stop the disease from spreading throughout the flock. A good feed or hatchery manager can give you helpful advice on many day-to-day problems.

Budgeting:

Included in this publication are two cost of production budgets: one for tom turkeys and one for hen turkeys. The budgets assume the production of three 1,000-bird flocks per year with the hens being sold at 14 weeks of age (or approximately 15 pounds) and the toms being sold at 17 weeks of age (or approximately 28 pounds). These budgets should help ensure that you include all costs and receipts in your calculations. Costs may be difficult to estimate in budget preparation because they are numerous and variable. Therefore, think of these budgets as an approximation, then make appropriate adjustments using the "your estimate" column to reflect your specific production situation. More information on using livestock budgets can be found in Enterprise Budgeting Analysis.

You can make changes to the interactive PDF budget files for this publication by inputting your own prices and quantities in the green outlined cells for any item. The cells outlined in red automatically calculate your revised totals based on the changes you made to the cells outlined in green. You will need to click on and add your own estimated price and quantity information to all of the green outlined cells to complete your customized budget. When you are done, you can print the budget using the green Print Form button at the bottom of the form. You can use the red Clear Form button to clear all the information from your budget when you are finished.

Sample Budget Worksheets

Initial Resource Requirements (Based on data from 2005 - Use budget sheets above to calculate exact production estimates):

LAND

1 acre for production - minimum of 5 acres for manure disposal

LABOR

- average of 1.6 hours per day per 1,000 birds

- 42 weeks per year for three flocks of hens

- 51 weeks per year for three flocks of toms

CAPITAL

- $6,750-40' x 100' building (10 year expected life) or existing structure

- $16,422.50 expenses for hens, without building

- $31,490.00 expenses for toms, without building

For More Information:

- Bland, D. C. Turkeys: A Guide to Management, The Crowood Press, 2000.

- Feltwell, R. Small Scale Poultry Keeping: A Guide to Free Range Poultry Production, Faber & Faber, Ltd., 1992.

- Graves, W. Raising Poultry Successfully, Williamson Publishing, 1985.

- Mercia, L. S., E. Sears, and J. Grimes. Storey's Guide to Raising Turkeys: Breeds, Care, Health. Storey Books, 2001.

Online Resources:

- USDA, National Agricultural Statistics Service

- USDA, Economic Research Service, Livestock, Dairy and Poultry Outlook

- University of California Poultry Web Page

- National Wild Turkey Federation

- Oklahoma State University, Breeds of Turkeys

- Texas A&M Poultry Science

Producer and Marketing Associations

National Turkey Federation 1225 New York Avenue NW, Suite 400 Washington, D.C. 20005 Telephone: 202-898-0100 Fax: 202-898-0203

National Poultry and Food Distributors Association 958 McEver Road Ext., Unit B-8 Gainesville, GA 30504 Telephone: 770-535-9901 Toll free: 877-845-1545 Fax: 770-535-7385

U.S. Poultry and Egg Association 1530 Cooledge Road Tucker, GA 30084-7303 Telephone: 770-493-9401 Fax: 770-493-9257

Major Turkey Breeders:

For information on regulations regarding home processing and other aspects of turkey flock management, contact Amy Barkley, Livestock and Beginning Farm Specialist with the SWNY Dairy, Livestock, and Field Crops Team at 716-640-0844 or amb544@cornell.edu. If you do not live in the SWNY region, please reach out to your local extension office.

Upcoming Events

WEBINAR - Automated Milking Systems Efficiency: Balancing Focus on Individual Cows and System Optimization

May 8, 2024

Please join Cornell the SWNY team and MSU Extension for our talk with Dr. Pablo Silva Boloña on improving efficiency of Automated milking systems by focusing on milking settings for individual and group success.

Broiler Field Day at Sunny Cove Farm

June 6, 2024

Alfred Station, NY

Join us for a field day to explore broiler production, processing, and finances. Meghan Snyder of Sunny Cove Farm will be our host. She raises small batches of organic broilers, processing them on-farm under the 1,000 bird exemption.

Stockmanship and Stewardship 2024

October 25, 2024

Hamburg, NY

Save the date!! The event is one of 4 across the US and is a two-day educational experience featuring low-stress cattle handling demonstrations, Beef Quality Assurance educational sessions, facility design sessions, and industry updates.

Announcements

No announcements at this time.